The demand planning function is regarded as the process of predicting the demand for services and products, which helps in their delivery in an effective manner for customer satisfaction. It is regarded as a crucial phase of supply chain planning.

Supply chain planning and supply chain execution are considered to be the crucial components of supply chain management. The SCM’s (Supply Chain Management) planning side begins with the demand planning function process. It includes the creation of a demand plan according to the statistical forecast.

It takes various factors into account that impact the demand, like marketing and inventory, along with the specifics of the distribution of the product, to accomplish the anticipated demand. This specific demand plan is integrated into the next immediate steps within the supply chain planning process: product planning and material requirements planning. After the product is manufactured, it will enter the SCM’s execution stages, along with the transportation management and warehouse.

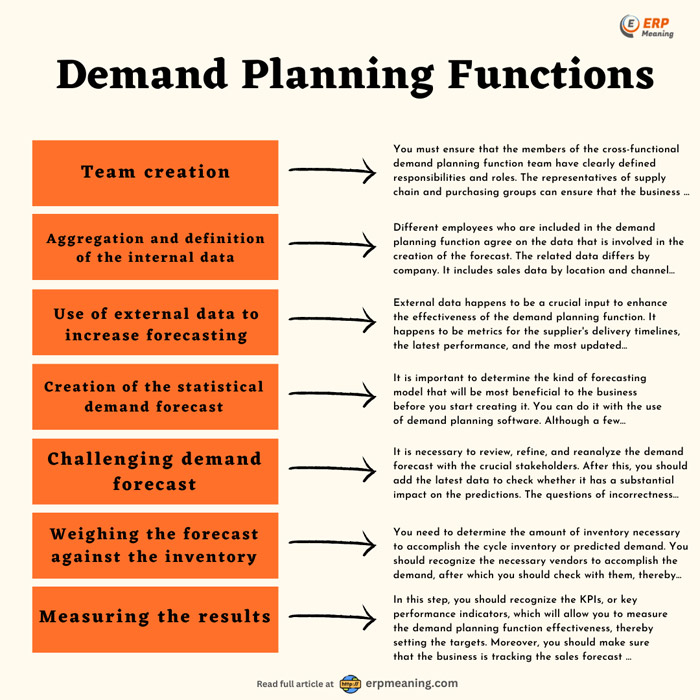

List of Demand Planning Functions

The demand planning function involves sales analysis, consumer trends analysis, historical sales analysis, and seasonality data analysis, which helps in the optimization of the capabilities of the business to accomplish customer demands effectively. To accomplish the objectives, the demand planning function combines supply chain management, sales forecasting, and inventory management. Initially, it makes the right use of the data from different external and internal sources to forecast future demand.

The demand planning function refers to a multi-step process. It will be complex, given the growth of the forecasting efforts and the scope and size of the company. The crucial steps that are essential for the successful demand planning process include:

Team creation

You must ensure that the members of the cross-functional demand planning function team have clearly defined responsibilities and roles. The representatives of supply chain and purchasing groups can ensure that the business has sufficient inventory so that they can accomplish the demand predictions. Such a financial team owns the responsibility to create the original forecast.

Aggregation and definition of the internal data

Different employees who are included in the demand planning function agree on the data that is involved in the creation of the forecast. The related data differs by company. It includes sales data by location and channel, inventory turnover, out-of-stock rates, production times, lead times, obsolete inventory, and different crucial inventory metrics.

It is recommended to connect with the marketing and sales teams about the marketing campaigns, price change timing, and promotions that are impacting demand. You should collect information from different product teams regarding retirees, new releases, and competitive offerings, which will affect the forecast accuracy.

Use of external data to increase forecasting

External data happens to be a crucial input to enhance the effectiveness of the demand planning function. It happens to be metrics for the supplier’s delivery timelines, the latest performance, and the most updated purchasing habits of the potential audience. Other external details are inclusive of the economic conditions, which will have an effect on the shifts and sales in the market.

Creation of the statistical demand forecast

It is important to determine the kind of forecasting model that will be most beneficial to the business before you start creating it. You can do it with the use of demand planning software. Although a few businesses use Excel and other tools that require manual work, they are prone to errors. Beyond the company-wide forecasts, you are willing to create the projections by product line or product.

Challenging demand forecast

It is necessary to review, refine, and reanalyze the demand forecast with the crucial stakeholders. After this, you should add the latest data to check whether it has a substantial impact on the predictions. The questions of incorrectness will remove the outliers, which will distort the forecast to understand the impact to do so. Hence, it is considered a suitable time to double-check that the specific demand forecast will align with the broader financial forecast of the company.

Weighing the forecast against the inventory

You need to determine the amount of inventory necessary to accomplish the cycle inventory or predicted demand. Also, you should recognize the necessary vendors to accomplish the demand, after which you should check with them, thereby ensuring that they will deliver the prerequisite services and products within the necessary timeline.

You should make sure that the transportation vendors have the ability to manage the volume, thereby accomplishing the schedule for the creation of the goods between different locations.

Measuring the results

In this step, you should recognize the KPIs, or key performance indicators, which will allow you to measure the demand planning function effectiveness, thereby setting the targets. Moreover, you should make sure that the business is tracking the sales forecast accuracy, fill rates, inventory turns, cost of goods sold, and order fulfillment lead times. Moreover, you should make sure to review the performance consistently against the targets to create adjustments according to the needs.

Importance of the demand planning function

It is of utmost importance to keep up with product demand. If you fail to do so, there are risks that there will be a loss in revenue and customers. One of the primary objectives of demand planning is finding the right amount of inventory necessary to accomplish the customer demand without the need to waste your valuable money or face any shortage to create and store the surplus inventory.

The demand planning function plays an integral role in reducing the bullwhip effect. It refers to the phenomenon in which retail demand fluctuations will amplify the demand from the previous supply chain actors. Better and more effective communication among different supply chain participants and enhanced accuracy of demand forecasts will reduce the bullwhip effects.

Future of demand planning function

An increase in the availability of real-time data and the use of advanced analytics in machine learning and artificial intelligence techniques are useful in improving forecast accuracy. The use of mobile devices and cloud-based collaboration tools improves the capabilities of the demand planners for the sharing of information and the ability to react more effectively to changes in supply and demand.

The drive towards a digitized business process helps to connect a wide assortment of supply chain participants, from the raw materials supplier to the manufacturer to the potential customers, to offer finer-tuned control over the movement of different goods. Such broader trends offer new support to the longstanding effort to create what the industry analysts and the vendors will call the demand-driven supply chain, where the supply chain will be more responsive to the original consumer demand.

Where Does Demand Planning Function Fit with an Enterprise?

To make the demand planning function successful, it needs input from the coordination between different departments, such as purchasing, marketing and sales, finance, production, operations, and SCM. In addition, the executives responsible for product portfolio management and business strategy will play a crucial role while taking the lead time for production times and components into account.

The demand planning function influences different business functions and the location of the employee who will handle responsibility. It refers to the independent group, or it might be that it is integrated into either of the departments, the operations departments and procurement. The demand planning function is considered more successful when it is related to the marketing and sales teams.

Skills need to execute the demand planning function.

It is of paramount importance that demand planners have outstanding analytical skills along with competency in statistical data analysis and data modeling. Apart from the numerical skills, a successful demand planning function is regarded as requiring communication skills, which require interaction with various departments.

They should be innovators, which the champions get through automation, as tools like supply chain management ERP software and demand planning software are useful to the business in improving demand planning, thereby saving valuable money. It is important that the demand planning function be familiar with the ERP, or enterprise resource planning systems, as they will be the data source, thereby making them expert demand planning software users.

Methods of Demand Planning

Speaking of the broadest level, pull and push are regarded as the two philosophies applicable to the demand planning function process. The push methodology enjoyed high popularity in the 20th century. The business adopts a specific approach for the creation of innovative products, which will create demand for them.

It ensures that the manufactured products are readily available to their potential audience. The success of the specific strategy is a miss or hit in practice. At times, demand exceeded supply, indicating missed sales opportunities for the company. There are times when unsold products on the shelves and increased costs affect cash flow negatively. Businesses achieve the prerequisite balance rarely, primarily with sales and markdowns.

In the present day, the majority of demand planning function processes opt for the pull philosophy. It begins with the use of customer demand and the use of specific information to seize the operational planning opportunity.

The prerequisite challenge of the specific pull approach is adopting the customer demand forecast. Inaccurate forecasting leads to the same issues as the push methodology, increased costs, and missed revenue opportunities. The common models responsible for the creation of the statistical forecast within the demand planning component’s demand forecasting component are:

Linear regression

Such a methodology adopts the past demand levels and integrates them through the least-squares regression statistical model to forecast future sales. Such a model is regarded as the line of best fit, which includes a curve according to the past demand and extends the specific curve for the creation of future demand.

Movement of the average demand

Such methodology will assume that the future prediction will be the last sales period’s rolling average.

Sales forecast

Such a methodology will estimate the future demand, according to the probabilities and sales opportunities the company recognizes for the upcoming period.

Seasonal trends

As per the name, the seasonal trends methodology will predict future demand according to historical sales during the seasons and specific months. Such a kind of methodology is considered to be the most appropriate option for different businesses with highly seasonal sales.

There are wide assortments of businesses that adopt the demand planning function in combination with the methodologies for the automation of specific aspects of forecasting and modeling. The software helps make demand forecasting more accurate and robust.

Best practices to execute the demand planning function

The demand planning function is complicated at times. To improve accuracy, the best demand planning function practices rely on collaboration. A few of the best practices in this regard include:

- Seeking buy-in and demanding accountability from different stakeholders by depending on collaborative forecasts and statistical modeling for the extraction of data from different departments.

- Using accurate inventory data. It is not possible to get success in the demand planning function without an effective accurate inventory management process.

- You should shape the demand actively with pricing tools, promotion, and marketing.

- Use of information from market shifts, natural disasters, weather events, the supply chain, and consumer buying behavior in the forecasts. This process is regarded as demand sensing.

- Another prominent practice of the demand planning function is using due diligence when selecting the demand planning software. The software needs to automate different tasks, like the monitoring of KPIs, statistical analysis to forecast, and calculation of the optimal stock levels, which will provide a suitable opportunity for the team to interpret the desired results, adjust the plans, and collaborate with different groups. It is important that the software is intuitive and user-friendly, and that you can integrate it with the ERP (Enterprise Resource Planning) systems and inventory management.

Conclusion

The demand planning function is useful to enterprises in enhancing forecast accuracy. The software will connect to the point-of-sale data, which helps to extract the information from the distributors and suppliers, thereby allowing the business to integrate data in real-time into the planning and analysis.

The demand planning function opts for machine learning and artificial intelligence to process massive amounts of data and recognize patterns and trends that cannot be identified by humans. The demand planners make the right use of the insights for the creation of adjustments.