The steel industry has experienced tremendous growth in recent years, largely due to the increasing number of infrastructure projects. Enterprise Resource Planning is an indispensable tool for every type of business, and it works just as marvelously with the steel sector. ERP offers powerful capabilities that can take your steel operations to new heights. Steel ERP is specifically tailored to the unique needs of steel businesses, and it can help you streamline operations, increase productivity, and reduce costs.

As steel demand continues to skyrocket, organizations in the industry are experiencing a dramatic rise in operational and maintenance costs. Steel firms are exploiting the potential of steel ERP software to improve efficiency, reduce costs and optimize operations. But that’s only scratching the surface! When this top-notch solution is effectively put into action, companies can reap a plethora of additional benefits.

What is Steel ERP?

Steel ERP offers an immense opportunity for steel and metal manufacturers to maximize production! This specialized software helps streamline inventory management, keep track of profit margins, and monitor shipments. With ERP customization capabilities to ensure your unique needs are met efficiently, this isn’t a one-size-fits-all solution that won’t disappoint.

ERP for steel industry is essential for managing and tracking data, generating reports, controlling inventory levels, and making accurate forecasts. ERP systems are crucial to successful businesses in any sector; however, they become even more indispensable in steel production due to their complex operations that necessitate strict oversight over every area of the organization. An efficient steel ERP software must integrate seamlessly with the other applications in a business and possess an effective data entry system. Additionally, it should be capable of producing comprehensive reports – either on demand or regularly scheduled for managers at all levels within the company.

Benefits of Steel ERP

A steel manufacturing company must go through many steps before they commence production. The ideal ERP system for steel businesses simplifies complex administrative processes quickly and competently, making it an invaluable tool in the industry.

1. Cross-company Integration

Before beginning the production process, a steel manufacturing company must abide by several procedures. Fortunately, the correct ERP solution for the steel industry can make these tedious administrative processes much easier and more efficient.

2. Multiple planning strategies

Steel manufacturing companies employ a variety of planning strategies in their production process. For instance, the make-to-stock strategy is often used to manufacture steel bars and long sheets, while the more customized make-to-order approach is typically utilized for producing steel strips or flat products.

Costing products that are made to stock can often be a complicated process, but it doesn’t have to be. A reliable ERP system is essential in curtailing complexity and facilitating sound planning strategies.

ERP for steel industry is a powerful tool that can streamline production processes, enabling users to monitor different strategies and records easily and quickly.

3. Time Saving

Time is of the essence when it comes to production and delivery deadlines. ERP for steel industry helps operators easily optimize their scheduling and helps them keep track of all tasks in real time, allowing for more timely deliveries.

4. Great Visibility for Important Data and Processes

ERP softwares provide steel manufacturers with a smooth flow of data across the organization, allowing users to access pertinent information from any place and at any time.

This feature accelerates organisational productivity and gives owners and managers a wide-angle perspective of all critical processes and data. It ensures full clarity for those at the top, enabling them to make informed decisions with complete transparency.

5. Specified Business Forecasts

Steel is in unprecedentedly high demand due to the need of various industries, such as construction, heavy equipment manufacturing, bridge building, automotive engineering and airline maintenance. For this reason, there must be a meticulous synchronization between business forecasts, market trends and digital orders.

To ensure accurate business predictions, the integration of different corporate systems is a must. Steel manufacturing ERP can be incredibly useful for forecasting, recognizing market trends, predicting needs and integrating your business processes. This will help you stay one step ahead and give you an edge over competitors.

6. Control the Expenses

ERP is the perfect choice for your steel manufacturing business to have complete control over all financial matters. This will ensure you have maximum oversight of budgeting and expenses associated with any project, leading to optimal management.

With a firm grasp on your finances and business operations, you can quickly identify areas of increasing expenditure and any unnecessary costs – allowing you to take swift action towards their minimization.

7. Variations of Product

By comparing the development of steel grades over time, you can see just how far we’ve come. At the beginning of the 1900s, plain steel rods and bars were used for production; however, ribbed bards had appeared on the scene by its end.

As the century progressed, we saw a surge in remarkably solid and sturdy bars that underwent thermo-mechanical treatment. Whenever grades shifted, it was obvious that their raw material structure had also changed accordingly.

With an ERP solution, the floor manager can design components tailored to each order while managing processes from sales orders to finished products. This cuts down on confusion and helps streamline operations.

8. Easy adoption of Production Processes

As steel needs and demands shift over time, ERP allows for the easy adaption of production processes. This eliminates any confusion or delays due to a lack of knowledge about the latest industrial trends.

Steel manufacturers can also easily scale up and down their operations according to customer demand; with an ERP solution, this task is incredibly simple. They can also integrate existing production and business systems to create a more flexible workflow.

9. An integrated model of IT

ERP systems boost productivity in steel manufacturing facilities by providing an integrated IT model, enabling parallel processing and sharing of data for every step of the process, from raw materials to order shipments. This powerful system offers reliable support throughout the entire production pipeline.

ERP systems have greatly evolved and are now more efficient than ever. They provide comprehensive solutions that include inventory management, process controls, reports, forecasts, production schedules planning, shipment tracking, and human resource management, among others.

10. Improve the Tracking of Inventory

Steel ERP’s integrated inventory module lets you keep a tight grip on stock movements, making warehouse management effortless and efficient. Additionally, Steel ERP can predict and measure the volume of raw materials or semi-finished goods that are essential for your production process.

Our software’s real-time inventory details equip you to integrate the cycle of demand seamlessly. Consequently, as soon as a bill of materials is produced, you can easily determine if your storehouse has all the necessary components available.

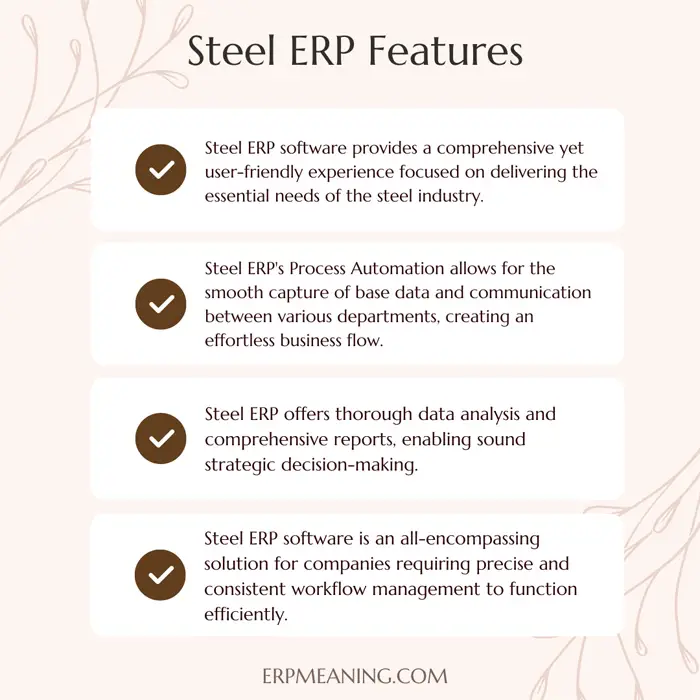

Steel ERP Features

- Steel ERP software provides a comprehensive yet user-friendly experience focused on delivering the essential needs of the steel industry.

- Steel ERP’s Process Automation allows for the smooth capture of base data and communication between various departments, creating an effortless business flow.

- Steel ERP offers thorough data analysis and comprehensive reports, enabling sound strategic decision-making.

- Steel ERP software is an all-encompassing solution for companies requiring precise and consistent workflow management to function efficiently.

Top 5 ERP for the steel industry

1. Real Steel

Wolcott Group’s RealSTEEL™ is ERP software engineered specifically for the steel industry. It builds on Microsoft Dynamics 365 Business Central’s already versatile capabilities to offer a suite of features and advantages designed with the specific needs of steel and metal manufacturers in mind. With this solution, producers are granted incomparable visibility into their operations from one platform, allowing them to take control of even the most intricate aspects of their business.

2. Epicor ERP

Epicor for Manufacturing offers unparalleled insights into your main business activities, so you can get rid of unnecessary steps and streamline operational management. The component-based design allows it to be easily implemented across the whole range from marketing and sales to planning and production, procurement, and customer service up until finance. Epicor ERP also facilitates automating operations, leading to reduced costs while optimizing efficiency in real-time.

3. Infor ERP

Infor ERP is a comprehensive solution for steel and metal producers, equipped with all of the essential components for seamless integration. It offers various features such as supply chain management, integrated financials, dynamic inventory tracking and more.

4. Oracle Netsuite

Oracle NetSuite is an end-to-end, fully integrated ERP solution for the steel industry. It is designed to provide complete visibility into every aspect of your business, increasing productivity. The suite offers robust customer relationship management (CRM) capabilities and deep financial integration, enabling both finance and sales departments to share data in real-time.

Read also: How much does Oracle Netsuite cost?

5. SAP ERP

SAP ERP is the world’s leading ERP solution and provides unparalleled insights into all aspects of your business. It offers a comprehensive set of features such as inventory forecasting, production planning, automated warehouse management, etc. The system enables decision-makers to gain full control over their operations, enabling them to make informed decisions and stay ahead of the competition. It can also provide complete visibility into customer demands and sales trends, allowing for better forecasting and inventory management.

Conclusion

Steel ERP is an invaluable asset for steel producers looking to increase efficiency and productivity. It provides a comprehensive yet user-friendly experience tailored to the industry’s unique needs. With features like process automation, real-time inventory tracking and deep financial integration, these solutions enable companies to gain full control over their operations and stay ahead of the competition. No matter the size of your business, there is an ERP solution out there that can help you unlock greater organizational potential. Choose wisely and reap the rewards.

The right steel ERP software will be invaluable for steel producers looking to increase efficiency and productivity. With features like process automation, real-time inventory tracking and deep financial integration, these solutions enable companies to gain full control over their operations and stay ahead of the competition. Whether you are a large or a small steel producer, there is an ERP solution that can help you unlock greater organizational potential. You can reap the rewards of utilizing one of these powerful products with careful consideration.

Now that you know more about the key features of steel ERP, it is time to consider which solutions best fit your needs. While several great options are available, Epicor ERP, Infor ERP and Oracle NetSuite offer unparalleled insights into all aspects of steel production and are trusted by leading players in the industry. You can make an informed decision for your business with a deeper understanding of the options available.