ERP system validation may sound like a complicated process, but it is quite straightforward: Does the software work as advertised? ERP validation systematically tests software to ensure that it meets the requirements outlined in the project’s scope of work.

As ERP software is important for all businesses, especially regulated industries. All businesses should validate their ERP implementations to ensure proper outcomes, but firms in regulated industries such as banking or life sciences are legally required to validate their system.

When a business validates its ERP software, the company is not validated checking to see if the software meets compliance and process needs. Most good ERP solutions will meet those requirements, and any credible system having an effective solution that performs what is needed for validation should take priority.

ERP System Validation is important for all businesses, especially those in regulated industries. All businesses should validate their ERP implementations to ensure proper outcomes, but firms in regulated industries such as banking or life sciences are legally required to validate their system.

What is ERP System Validation?

ERP system validation ensures that a software product meets all defined requirements from both the business and customer-centric perspectives. The main purpose of performing this test is to ensure that the software meets all the pre-determined requirements and specifications while also fulfilling the customer’s needs in a real environment.

During ERP validation, every software component is put through a series of tests that help to assess its compliance concerning specific business processes. In addition, strategic ERP validation services help improve and focus company processes so the company can better utilize its strengths.

Overall, ERP validation is a crucial step in any software development project as it helps to guarantee that the end product will meet the needs of both the business and its customers. Organizations can avoid costly mistakes by taking the time to properly validate an ERP system and ensure that their ERP investment will pay off in the long run.

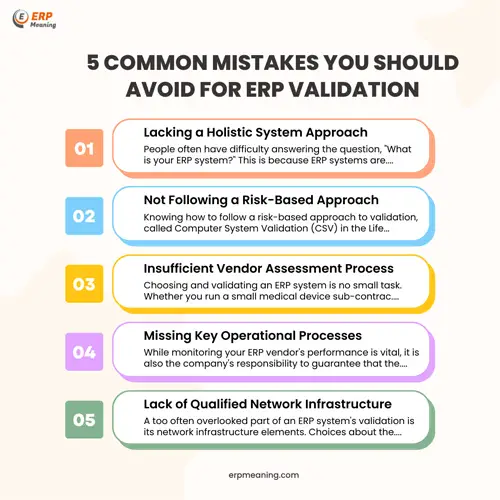

5 Common Mistakes you should avoid for ERP Validation

ERP systems are vital but often complex technologies that can drastically impact operations. If an ERP system is selected and implemented correctly, it will support efficient and effective operations. However, if the system is chosen poorly or not implemented properly, problems can arise. Often, ERP systems get blamed for issues caused by bad selection or implementation when this isn’t fair. Here are five mistakes often made during ERP selection and implementation that can lead to problems down the road:

1. Lacking a Holistic System Approach

People often have difficulty answering the question, “What is your ERP system?” This is because ERP systems are often made up of different parts that can be combined in various ways. They can be used on-premise or in the cloud. They can include many different ERP modules and features that come with the system. The system can help manage barcodes, labels, Master Batch Records (MBR), and Master Device Records (MDR). The system can also connect with other systems, like CRM, MES, and QMS. No laws say what your system should be, so it is up to you to decide.

Many factors, such as ERP integration, architecture, or configuration can influence the success of your validation process. Without knowing all the details about the system you’re working with, ensuring that every aspect is accounted for while trying to avoid duplicating any work becomes very challenging.

Trying to validate a system without having first defined it is a common and counterproductive mistake. The System Description section of ISPE, GAMP 5, can help you create the document you need to avoid this issue.

2. Not Following a Risk-Based Approach for ERP Validation

Knowing how to follow a risk-based approach to validation, called Computer System Validation (CSV) in the Life Science Industry, is of utmost importance. This involves assessing your system’s uses against risks that could compromise patient safety, product quality, or data integrity. ISPE, GAMP 5 is an industry-recognized framework that explains how this can be done; however, it is often not executed properly or altogether ignored.

Although an ERP risk assessment is time-consuming, it’s a crucial process. When we spend too much time testing and documenting low-risk aspects of a system solely for the sake of documentation, we’re adding unnecessary work with no real value. A risk assessment helps us avoid this by identifying missing requirements or features that could prevent health hazards such as product recalls.

3. Insufficient Vendor Assessment Process

Choosing and validating an ERP system is no small task. Whether you run a small medical device sub-contractor or a large pharma organization, ignoring due diligence with your potential ERP provider is a common mistake.

Evaluating a potential IT service provider is inherent to due diligence. This assessment should identify the risks of using this vendor compared to the controls they have in place for product/service development, delivery, and maintenance. A good vendor evaluation answers questions such as:

- Can you trust that the vendor’s internal processes will give you a system of excellent quality?

- Will the vendor’s Software Development Life Cycle (SDLC) ensure high quality for all future updates and ERP customizations?

- If you have any questions about this product, are vendor documentation or training programs available to support your users?

- Was the vendor’s system developed in compliance with your regulating requirements?

- If you can identify these answers, you’ll be able to manage the risks of working with this new vendor and adapt your validation strategy.

If you have an in-built ERP system, you might think that this mistake does not concern you. Nevertheless, it affects you more than you could imagine. Depending on your circumstances, a vendor assessment may not be the right option for the job. You should contemplate your internal operations and how much support your user base will need. These ideas were mentioned earlier and remain valid even if a vendor assessment is irrelevant to your business model.

4. Missing Key Operational Processes for ERP System Validation

While monitoring your ERP vendor’s performance is vital, it is also the company’s responsibility to guarantee that the system operates correctly. Internal process audits are crucial in this area. Depending on an organization’s level of expertise, this problem will belong (or, more likely, multiple categories) into one of three categories:

- General Quality Assurance (QA)

- Information Technology (IT) Management

- ERP System Use.

Quality Assurance Processes usually include how electronic records are managed by a company, employee training, and using electronic signatures.

The term “IT management” encompasses processes that support the administration of systems, for example:

- User provisioning

- Change management/release management

- Security

- Back-up & recovery

ERP system-use processes are those that define how users should interact with the system. System-use procedures could include entering a customer order, rejecting a defective product, or issuing a job floor order.

5. Lack of Qualified Network Infrastructure

A too often overlooked part of an ERP system’s validation is its network infrastructure elements. Choices about the design and implementation of the network infrastructure have serious consequences for the security, availability, speed, reliability, and data integrity it supports. Without careful planning, your enterprise might be in danger – regardless of whether your system uses a cloud-based ERP or not.

Qualifying your infrastructure independently from your ERP validation lets you validate each system thoroughly and not overlook important details. A Qualified Infrastructure is necessary for a Validated ERP System, so don’t couple the two closely together from a CSV perspective.

10 Steps for ERP System Validation

Developing an ERP System Validation plan prior to start will save you time and money and make the process more manageable. Locate a validation team that has both the time and power to follow through on each stage. Here are the ten essential steps for ERP System Validation:

1. User Requirements Document

Creating a user requirements document may seem daunting, but it’s actually quite simple. This document is different from a Request for Proposal (RFP) because RFP documents are usually more detailed and meant for larger businesses. All you need to do is create a quick list of one or two-line sentences that identify the functionality required for your business.

Prior to your ERP validation process, put together a team who will validate the functionality you need and brainstorm what those requirements are. For example: “The system must be able to track lot numbers for raw materials and manufactured products” or “An item needs to be able to have different quality control status.” By having this user requirement document ready, you’re more likely to select an ERP that fits all of your needs.

2. Project Plan

The project plan will specify who, what, where, and when validation occurs. A validation team which typically consists of the project manager, technical lead, quality assurance lead, validation lead, and support leaders, will oversee the process. The responsibilities for each team position should be detailed in the project plan. A project plan is key to the success of any project and should include a system description, purpose, environment specifications, assumptions, exclusions, limitations testing acceptance criteria, error resolution, and system documentation. Luckily there are various websites with samples and templates readily available.

3. Functional Specifications Document

Create a functional specifications document that contains more detailed information than the user requirements. For ERP System Validation, the functional specifications document should contain a list of all validation deliverables, assumptions, and risks. This document is used to develop test scripts so that you can ensure full system functionality. The user wants a connection between the functional requirements and the testing prerequisites so that they can confirm that their tests are accurate. This will create an accountability matrix that links your tests back to the original requirements.

4. GAP Analysis

A GAP analysis is conducted to determine what business needs are not being met by the current system. This is important to do during validation because you want to make sure that the ERP system you’re selecting can meet all of your needs – both now and in the future. The analysis will help you understand what processes need improvement and how the new ERP system can help.

5. Installation Protocol

The installation protocol will detail how the ERP software should be installed. This is important to have ahead of time because it will ensure that the software is installed correctly and avoid any issues later on. The installation protocol should be created by the vendor and reviewed by the validation team.

6. Installation Report

Once the software is installed, an installation report should be generated. This report will document any issues that arose during installation and how they were resolved. It’s important to have this report because it can help prevent future issues and provide a reference for future installations.

7. Operational Protocol

The operational protocol will detail how the ERP system should be operated. This is important to have because it will ensure that the system is used correctly and avoid any issues later on. The operational protocol should be created by the vendor and reviewed by the validation team.

8. Operational Report

Once the system is up and running, an operational report should be generated. This report will document any issues that arose during the operation and how they were resolved. It’s important to have this report because it can help prevent future issues and provide a reference for future operations.

9. Test Summary Report

Once all testing is complete, a test summary report should be generated. This report will document the results of all testing, as well as any issues that were found. It’s important to have this report because it can help prevent future issues and provide a reference for future testing.

10. Final Report

Once all validation is complete, a final report should be generated. This report will document the results of the entire process, as well as any lessons learned. It’s important to have this report because it can help prevent future issues and provide a reference for future validation.

Benefits of ERP System Validation

FDA Validation for ERP offers documented proof that your ERP solution is correctly set up to meet both your company’s internal processes and external regulatory standards. This type of validation is necessary for computer systems used in managing, controlling, and monitoring the creation and distribution of medical devices and pharmaceutical products. Here are some big benefits your business can experience from utilizing ERP Validation, even though FDA Validation is required:

-Saves your business time and money by getting it right the first time

-Ensures that all processes are compliant with FDA standards

-Demonstrates to the FDA that you take quality and compliance seriously

-Provides a roadmap for future ERP system expansion or updates

-Identifies process improvements that can be made to increase efficiency

-Creates a baseline for future ERP system validation efforts

Features of ERP System Validation:

Validation is a process of testing the ERP product to answer the question, “Are we developing the right ERP product?” Furthermore, its identification during verification allows for defects that were missed by the testing team. Other features include:

-Review of requirements

-Identification of the validation approach

-Development of test scripts

-Execution of test scripts

-Identification and documentation of results

-Preparation of final report.

Why is ERP Validation Required?

ERP validation is typically required by organizations that are subject to FDA regulation. For example, medical device manufacturers, pharmaceutical companies, and biotechnology companies must validate their ERP systems in order to ensure compliance with FDA regulations. Additionally, ERP validation may be required by other regulatory bodies, such as the Securities and Exchange Commission (SEC) or the Sarbanes-Oxley Act (SOX).

ERP validation is also important for organizations that are not subject to FDA regulation but still need to ensure the quality of their ERP systems. For example, companies in the automotive industry often validate their ERP systems to ensure compliance with ISO/TS 16949, a quality management standard for the automotive industry.

In summary, ERP validation is a process of testing the ERP product to answer the question, “Are we developing the right ERP product?” Furthermore, its identification during verification allows for defects that were missed by the testing team. Additionally, ERP validation may be required by organizations in order to ensure compliance with FDA regulations. Finally, ERP validation is also important for organizations that are not subject to FDA regulation but still need to ensure the quality of their ERP systems.

Conclusion

ERP validation is a process of testing the ERP product to answer the question, “Are we developing the right ERP product?” Furthermore, its identification during verification allows for defects that were missed by the testing team. Additionally, ERP validation may be required by organizations in order to ensure compliance with FDA regulations. Finally, ERP validation is also important for organizations that are not subject to FDA regulation but still need to ensure the quality of their ERP systems.