Manufacturing materials cloud inventory management system aids manufacturers in managing their supply levels and automating their processes. Manufacturers may use the appropriate software to reserve actual items based on minimum quantities and customer orders. Products required for production and repair are coded, allowing users to determine the remaining amount while predicting order durations.

Tracking raw materials, finished goods in inventory, and work-in-progress (WIP) assists company owners in making accurate financial predictions, such as sales forecasting using real-time data collection.

Cloud-based Manufacturing Inventory Management is the latest technology that offers an efficient and streamlined way to manage your production. Since you may access your inventory from anywhere, keeping track of your supplies and streamlining your manufacturing process is simpler. We’ll investigate how Manufacturing Inventory Management may assist you improve your manufacturing control/assembly, kitting, manufacturing order, work order, and material list in this blog article. We will also explore some advantages of using cloud inventory software for manufacturing tasks and why having an ERP Software for Manufacturing is important. Read on to know more info on cloud inventory manufacturing materials.

What is Manufacturing Inventory Management?

Manufacturing inventory management keeps enough stock on hand so production lines can fulfill orders. The process helps managers see stock levels at a glance and tracks raw materials, parts, work-in-progress and finished goods. Manufacturers can avoid stockouts and ensure quality control by keeping tabs on inventory. Manufacturing inventory management systems are sometimes integrated with other business software, such as accounting and enterprise resource planning (ERP) platforms. This gives managers a complete picture of the manufacturing process and helps them make data-driven decisions about production. When done correctly, manufacturing inventory management can help businesses optimize their operations and improve their bottom line.

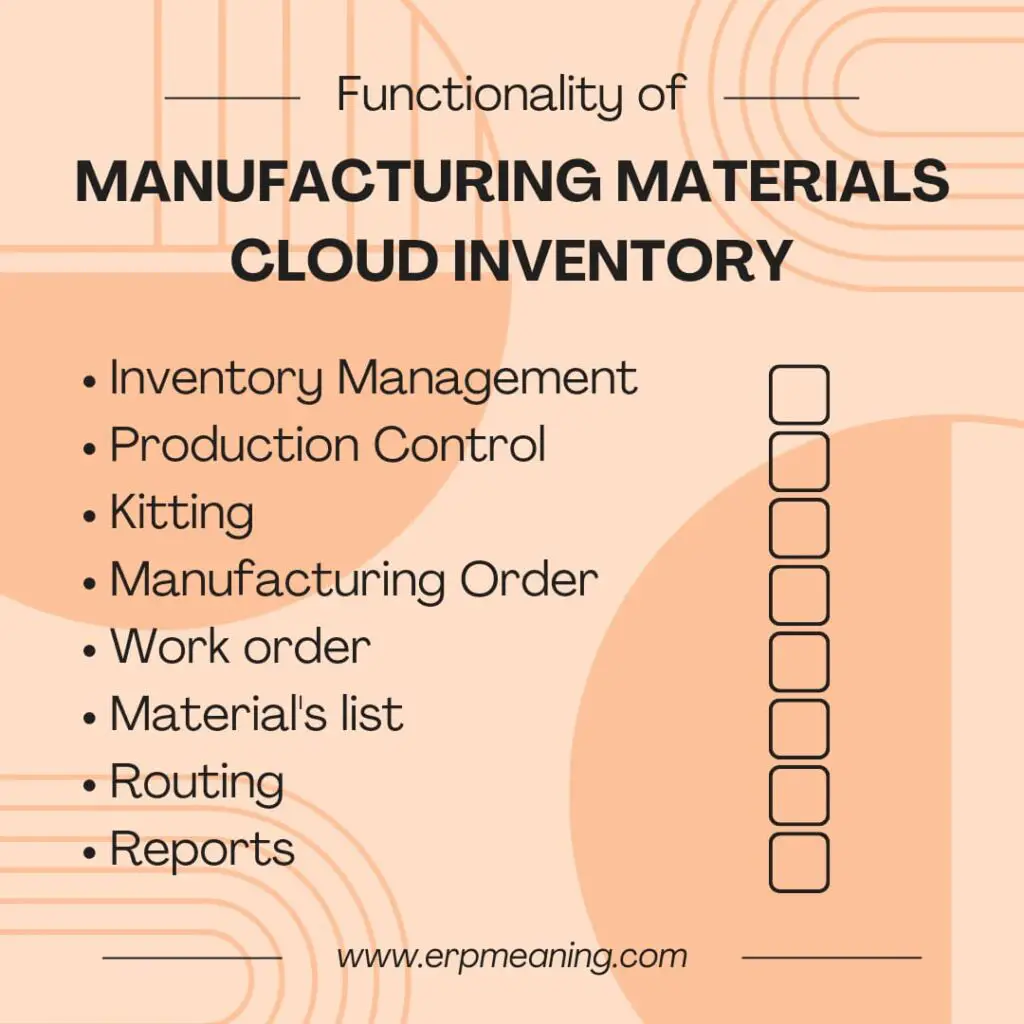

The functionality of Manufacturing Materials Cloud Inventory

The ability to access your inventory from anywhere at any time is one of the key advantages of using a cloud-based manufacturing inventory management system. This can be extremely helpful if you need to keep track of your materials and streamline your production process. A cloud inventory system for manufacturing materials can offer several benefits for your business. Here are some of the key functions that such a system can provide:

- Manufacturing Inventory Management: A cloud inventory system for manufacturing can help you keep track of your raw materials, finished goods, and work-in-progress. This information can be beneficial in forecasting sales and managing the production process.

- Production Control/Assembly: A cloud inventory system can help you manage your production control and assembly processes. This can include keeping track of the materials needed for production and ensuring that the correct parts are available when needed.

- Kitting: A cloud inventory system can also manage kitting processes. This can help you ensure that the correct materials and parts are available and that orders are fulfilled correctly.

- Manufacturing Order: This is the manufacturing process’s instant, including the number of items to be manufactured, the materials required, and the project supervisor or manager.

- Work order: This function aims to keep track of the production process, monitor semi-produced WIP goods, and make it easier for manufacturers to record order development. It’s possible to add the following features as part of a shareable document: change materials, complete time, and incorporate other information. The function is linked to the plant’s inventory list and allows authorized users to make any necessary modifications, including those for which materials are used and the anticipated completion time.

- Material’s list: The bill of materials lists all the raw materials and components required to manufacture completed items.

- Routing: Routing defines the sequence of operations required to manufacture a product. A manufacturing route typically includes information such as the machines to be used, the order in which the functions are to be performed, and the time each operation will take.

- Reports: Reports give you visibility into your inventory levels, production process, and more. This knowledge may help you improve your manufacturing process by making smarter data-driven choices.

Uses of Cloud Inventory Manufacturing Materials Software

You can use a cloud inventory system for manufacturing materials in many different ways. Here are some of the most common uses:

Advance feature of BOM(BILLS OF MATERIALS) for Manufacturing tasks

A bill of materials, also known as a recipe for a specific meal or a chemical formula, is a list of components needed to construct a completed item. ERP for Manufacturing adds extra functionality to the basic list format by allowing you to include operational instructions on each step of the manufacturing process. Many production stages may be included in a bill of materials (BOM), thus you must finish them all before moving on to the next. And that’s just the tip of the iceberg. A BOM may contain specific quantities, one-time goods, and option groups.

Processing Multiple Work Orders

Orders are the lifeblood of any manufacturing operation. There’s nothing that triggers production management than when you get them wrong. It can also throw your inventory control into chaos. Ordering is an excellent method to keep track of several work orders simultaneously. You can use it to monitor their progress, make changes on the fly, and even add or remove products from the order.

Generate Manufacture Order Purchase Orders Automatically

Cloud-based Manufacturing Inventory Management: How to Streamline Your Production

A manufacturing order (MO) is a work order used to track the production of finished goods. In most cases, an MO will be generated automatically from a sales order or a customer request. The bill of materials (BOM), routing, and quantity are all included in this file, which contains all the information required to manufacture the product. If you know more about manufacturing materials cloud inventory, you can help streamline your production.

Assess Work Order For Disassembly And Maintenance

Work orders aren’t only used to create new goods. You may need to take a returned item apart or add new components to it to satisfy a customer’s demands. That is why Manufacturing Materials Cloud Inventory allows you to use its work orders to create items and disassemble, repair, upgrade, and customize them in the warehouse.

Help Pricing By Estimating Final Costs

Manufacturing Materials Cloud Inventory can help you price your products by estimating the final cost of each item. This includes the cost of materials, employees, and overhead. You can also add a mark-up to cover your profit margins. The software makes it easy to adjust prices on the fly to stay competitive in the marketplace.

Deliver Invoices And Packing Lists Fast

You can use Manufacturing Materials Cloud Inventory to quickly generate invoices and packing lists. This is helpful when you need to ship an order out as soon as possible. The software will also keep track of your inventory levels so that you can reorder items when necessary.

Reasons for Inventory Management in the Cloud

An online inventory management program may appear to be just another internet-based software to the casual observer. However, it’s a lot more than that. With a great user experience and exceptional connections, it provides numerous outstanding functions.

Here’s a rundown of some of the most essential characteristics of a cloud-based inventory management system:

Smooth Management System

A cloud-based inventory management system is as simple and easy as email sending. Log in using your login information, and you’re ready to go. The system lets you easily set your preferences for taxes, currencies, and warehouses. The cloud solution allows you to manage your inventory however you want without any problems.

Real-time Stock Updates

You can forget about the days when you had to wait until the end of the day or week to get an update on your stock levels. With a cloud-based inventory management system, you can check your stock in real-time from anywhere in the world. This means you can quickly and easily see how much product you have on hand at any time.

Access from anywhere

You have unrestricted access to your data, so you may view it. From anywhere in the world, you can access your company’s data and reports. This software only requires a computer and an internet connection. As a result, you are only a few swipes away from accessing your company.

You’ll also get a native mobile app for the most convenient user experience. This program is compatible with a wide range of devices and has an easy-to-use interface to allow you to access your data.

Optimize Error

Cloud-based inventory management software virtually eliminates stock errors and “stock walking,” as well as the chance of unintentional shortages. It incorporates automated procedures throughout the system, minimizing the inevitable mistakes that occur with inventory management. Because of this, all relevant information is immediately provided to all stakeholders, including the manufacturer and logistics partners.

Safety & Security of Business Data

The cloud is a very secure place for businesses to store their data. It’s often more secure than on-premises solutions. Cloud providers are vested in keeping their data centers secure because their business depends on it. The data center is constantly monitored for threats by teams of security experts.

Analytics & Advanced Reporting of Business Data

With a cloud-based inventory management system, you can get real-time insights into your business. The software provides advanced reporting features that allow you to track your inventory levels, sales, and more. This information can help you make informed business decisions.

Automate Supply Chain Management

With a cloud-based inventory management system, you can automate your supply chain. This means that you can connect your suppliers to the system so that they can automatically send you the products you need. This eliminates the need for manual communication and coordination between you and your suppliers.

Scalability

A cloud-based inventory management system is scalable so that it can grow with your business. Your data storage can be expanded without any problems if you need to add more users. Contrary to on-premises solutions, cloud solutions are scalable.

Uninterrupted Business Process

Your business will not be disrupted by a power outage or natural disaster. This is because the data center where your data is stored is located in a different location than your business. As long as there’s an internet connection, you can access your data.

Better Transparency & Collaboration

With a cloud-based inventory management system, you’ll have better transparency and collaboration within your organization. This is because all stakeholders will have access to the same information. As a result, everyone will be on the same page and can make informed decisions about the business.

Better Management of Warehouse Item Inventory with Cloud ERP

Many companies face difficulties in keeping track of their inventory items. There are various software solutions available that can help manage warehouse item inventory. One such solution is enterprise resource planning (ERP) in the cloud. Cloud-based ERP systems can offer several benefits, including real-time data visibility, scalability, and reduced IT costs. In addition, cloud-based ERP systems can be accessed from anywhere, at any time. Having multiple warehouses in different geographical locations can be a major benefit for companies. Companies can gain better control over their inventory and improve their overall operations by using ERP in the cloud.

Purpose of materials Inventory on Cloud ERP

ERP systems with an inventory module in the cloud have recently become popular to streamline the inventory process. Not only do they provide a clear and simple way to keep track of stock levels, but they also offer several other benefits. For example, ERP systems can help to optimize stock levels by reducing the need for manual tasks such as counting and reordering. In addition, ERP systems can help to improve customer satisfaction by providing up-to-date information on stock availability. As a result, ERP systems with an inventory module can offer many benefits for businesses of all sizes.

Type of Manufacturing Materials Cloud Inventory

Manufacturing materials cloud inventory can be divided into the following types:

- Raw materials: These materials will be used to create the finished product.

- Work in progress (WIP): This inventory has been started but not yet completed.

- Finished goods: The goods are ready to be distributed or marketed, and they have completed all of the phases of the process, verification, and approval in the company’s internal quality systems and standards.

- Use: The items in the warehouse that are in a particular condition as a result of the company’s business plan are referred to as strategic assets.

- Reserves: A manufacturer’s warranty is the assurance that a vendor will provide the goods or services advertised, and they are there to assist with any issue or calamity that may come up with the items for sale or delivery.

- In transit: The items must be delivered to the customer, but the reception has yet to be completed.

- Base: Purchase to keep them in stock. They will also agree to market demand’s demands when they put their items up for sale.

Importance of Manufacturing Materials Cloud Inventory

ERP systems can be used by any manufacturing company, whether it is big or small. Many advantages may be obtained by a small to large business if it employs ERP systems. To make informed judgments at every step, modern manufacturing firms must employ solutions and tools that aid them in accelerating growth and developing a data-driven culture.

Given today’s hyper-connected and data-driven environment, the power of analytics and big data can’t be overstated. ERP systems aid production and distribution improvement and provide a full business perspective by integrating various internal procedures.

It’s challenging to implement the appropriate manufacturing ERP system. It necessitates that you take into account a variety of variables, such as your budget, implementation goals, timeline, and required features and capabilities. Many sectors find an Enterprise Resource Planning (ERP) solution a wise investment. Here are some of the essentials of a manufacturing ERP software package.

Conclusion

Inventory management is vital for any business that manufactures or sells products. The goal of inventory management is to ensure that the right level of stock is maintained while minimizing the cost of holding inventory. Streamlining production and reducing costs can be achieved with an effective inventory management system.

Cloud-based ERP systems offer several advantages for businesses that manage inventory. ERP systems can help to optimize stock levels and improve customer satisfaction by providing up-to-date information on stock availability. In addition, cloud-based ERP systems can offer some benefits for businesses of all sizes. Make sure your ERP system includes an inventory module if you are considering implementing one. Doing so will help streamline your production process and improve your bottom line.

ERP systems are vital for the success of a business, no matter its size. Small businesses can use ERP to manage day-to-day operations, while larger businesses can manage complex supply chains. In either case, an inventory module is essential for businesses that want to streamline their production process and improve their bottom line. Choose a cloud-based ERP system that includes an inventory module, and you’ll be on your way to a more efficient and successful business.