Many people come to take a professional job through a system of production and distribution under their supervision. But you need to remember that always the process of production and distribution does not come in a systematic way which will surely provide you success in your future life. The systematic process between production and distribution comes through control systems. Before you come to use this system, you should come to know the system exactly. Take a look at the below.

What do you mean by Control system?

Control systems become the set of electronic or mechanical devices that regulate other systems or devices through the way of control loops. The system is surely a hundred percent computerized.

How does the Control System come to be used?

This system is used to understand production, safety, and efficiency in several industries. Take a look below at the industries.

- Agriculture

- Pulp and paper mills

- Chemical Plants

- Industrial and manufacturing quality control

- Boiler controls & power plant operations

- Environmental control

- Water & sewage treatment plants

- Food and food processing

- Pharmaceutical manufacturing

- Sugar refining

- Metal & mines

Examples of Control Systems in the industrial processes

The following are the specific examples from where the controlling systems are used in the industrial processes. The processes are mentioned below:

- Heating boiling controls and system of power plant

- Pipeline monitoring

- System of water distribution

- System of wastewater treatment

- System of electricity distribution

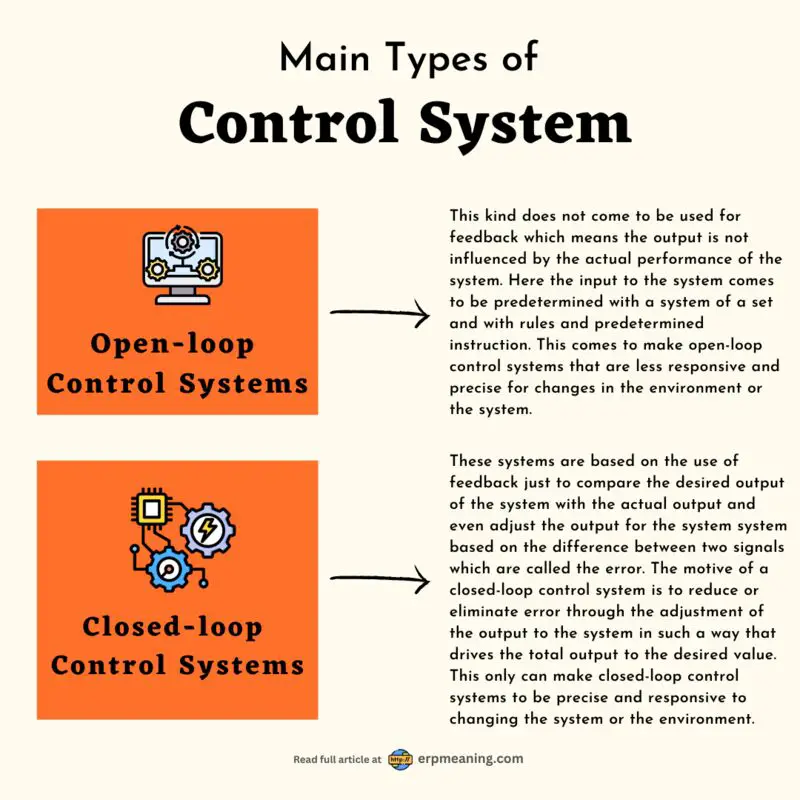

Types of Control System

There are numerous control systems but mostly two types come to be used. They are (1) Open-loop control systems and (2) Closed-loop systems.

1. Open-loop Control Systems:

This kind does not come to be used for feedback which means the output is not influenced by the actual performance of the system. Here the input to the system comes to be predetermined with a system of a set and with rules and predetermined instruction. This comes to make open-loop control systems that are less responsive and precise for changes in the environment or the system.

2. Closed-loop Control Systems:

These systems are based on the use of feedback just to compare the desired output of the system with the actual output and even adjust the output for the system system based on the difference between two signals which are called the error. The motive of a closed-loop control system is to reduce or eliminate error through the adjustment of the output to the system in such a way that drives the total output to the desired value. This only can make it precise and responsive to changing the system or the environment.

Apart from these two control systems, there must be several systems that are mentioned below. Just follow the systems below.

(i) Continuous Control systems:

These particular systems have been operating for a long time or output values. They are used for analog and digital signals for the presentation of the input as well as output of the system. The continuous control systems come to be used in the case of applications where a continuous output is needed especially for the temperature control system.

(ii) Discrete Control Systems:

These systems operate at discrete points in the exact time and the input and output both are represented by digital signals. Discrete systems are often used in need of applications where the output is only needed at particular points in time.

(iii) Linear control systems:

These particular systems come to be represented by linear differential equations which means the system dynamics are almost proportional to the input. Even it can be described through the use of linear mathematical operations. Linear control system runs through certain properties that make them relatively easy to control.

(iv) Nonlinear Control System:

These particular systems do not come to be represented by differential equations like linear and they may exhibit some odd behavior such as bifurcations and chaos. Nonlinear systems are more challenging just to analyze than linear systems and they may need specialized techniques.

(v) Time-invariant control systems:

These systems run with the same input or output relationship at all times which means the system dynamics do not come to be change over time. Here time-variant systems are often used for applications where the system parameters are not expected to vary over time.

(vi) Time-varying control systems:

The systems go with a time-varying input-output relationship that might be caused by changes in to the system for external or dynamic factors. Time-varying is more challenging just to analyze with controlling than the time-varying system.

(vii) Single-output & single input:

The particular system runs with a single input and single output. That means there is only a degree of freedom in the system. SISO systems are simple just to analyze and control and even for the basic systems.

(viii) Multiple-input & multiple-output:

These systems run with multiple inputs and outputs and even these are more complex to analyze and control than the SISO systems. MIMO systems come to be used for controlling multiple degrees of freedom.

Applications of Control System?

Control system applications are used through a wide variety of applications just to monitor automatically with controlling power for various processes and systems. Here are some examples of control system applications.

- Processes of Manufacturing & production: Here these systems come to be used to automate and optimize production processes in mills, factories with other manufacturing facilities.

- Building & home automation: These particular types come to be used just to automate and control lighting, heating, air-conditioning, and security.

- System of transportation: Here the systems come to be used just to automate and control several aspects of transportation systems like traffic control, railway signaling, and autopilot systems.

- Power generation with distribution: Controlling systems come to be used for monitoring and controlling the power with the system of distribution such as electric grinds and power plants.

- Medical equipment: Controlling systems come to be used to automate and control X-ray machines, dialysis machines, and some others.

- Agricultural and farming applications: Here the systems come to be used for automating and optimizing different kinds of farming and agricultural processes.

- Military and defense systems: In this application, systems come to be used for automation and control of various military defense systems like missile defense systems, radar systems, and drones.

- Robotics: Systems come to be used for designing and controlling the movement and behavior of the robots.

What is an Embedded Control System?

An embedded control system comes with a system that is integrated into a larger system or product. Embedded systems are used to automate and control the operation of the system or the product in which they are completely embedded.

Here are examples of the products and systems that may come to be used for embedded control systems:

- Automobiles: Embedded control systems are generally used to control the systems of engine, transmission, brakes, and suspension.

- Medical devices: This type of embedded system comes to be used for controlling various kinds of medical equipment like dialysis machines, X-ray machines, and others.

- Industrial equipment: The embedded system is designed to automate and control different types of industrial equipment such as mills, lathes, and robots.

- Appliances: This embedded system comes to be used for automation and controlling various types of appliances like refrigerators, washing machines, and microwave ovens.

- Consumer electronics: Embedded systems control various aspects of consumer electronics such as tablets, Smartphones, and televisions.

What is a control system designed with?

The control loops that make up the overall systems include a sensor and a controller with a final control element. The sensor comes to read the process even a related process controlling element. The sensor reads the process variable. Here the controller receives the accurate signal from the sensor and then forwards it to the instrumentation, the remote terminal units with final control elements. Here the process variable is adjusted just to keep it constant at the chosen point.

What are the demerits and merits of Control systems?

Closed-loop control systems are common to be used in many applications. They are much more effective in controlling externally located devices in providing and readily output data withstanding external disruptions.

Closed-loop systems are surely complex and these needs training documentation for the ultimate operation just achieves the desired output. Malfunctions regarding remote sensors give inaccurate data for the performance related to the systems. Their complexity tells that they are not fully ready to use the details out of the box.

However, the control systems are complex and these require training and documentation for the optimum operation to achieve the desired output. Malfunctions in remote sensors provide inaccurate data for the system’s performance. Their complexity means that they are not ready to use the details out of the box.

FAQ’s

How is feedback used to improve the performance of the control system?

Feedback control comes to be used just to improve the performance of a control system with the desired output of the system beyond the actual output. The system is lined by the desired output of the system for the actual output and adjusting the system to reduce errors and achieve other performance.

How can the stability of a control system be guaranteed and analyzed?

The stability of a control system can be analyzed through techniques such as root locus or frequency permits response analysis. The methods allow the designer to understand the way of system responds to different inputs. Here the stability can also be guaranteed by designing the system to meet robust control techniques.

How do control systems come to be designed to be robust for system parameters?

Robust control is used to design a control system that is completely resistant to variations in the system parameters. This can be succeeded by designing this system which is completely valued by algorithms.

How can control systems come to be designed for handling nonlinearities?

Nonlinear controlling techniques come to be used just to design control systems that easily handle complex behaviors. These particular techniques come to control algorithms, linearizing the system using feedback to cancel the effects of nonlinearities.

How can control systems after tested in practice?

This system comes to be implemented and tested through a variety of tools and methods and they are simulation tools, prototyping platforms, and others. Testing is an important step in controlling the designing process and it allows the designer just to verify the controlling systems.

How does the control system come for optimizing for a particular performance?

Control systems come to be optimized in need of a particular performance such as mining error through optimization techniques. These methods help to find the control of the inputs.

How can a control system come to be integrated with other systems?

Control systems will be integrated with other systems like communications networks and even software systems to exchange the data and control the signals. This can allow the record system to influence the behavior of the other systems.

How do control systems achieve a particular goal?

Control systems are used to achieve a particular goal with some awesome design to control the algorithm and even to produce the desired output with system architecture.

Conclusion

It is good to know that when you have a mind to set up a manufacturing company, you should go for the production of goods. In that case, you need to take care of the goods’ quality on which your customers get a good satisfaction. Customers’ satisfaction is the root cause of your product demands and as a result of that, your business turnover will increase day by day in leaps and bounds. Apart from that, you should keep the price of the product in such a way that customers from any economic background will be comfortable to purchase the product.

Not only production of the product in your business is the key factor but you need to give importance to the distribution of the products. In that case, you should keep an experienced and skilled team to work on the distribution of the products. That means, your business should go through production and distribution under the process of control systems.