Most of the time, business organizers cannot determine the best software either ERP or PLM as both of them provide several benefits in need of good performance in business. Both of the vendors claim that they can easily manage bills, costs, charges, and other information associated with products. To your best knowledge, you need to go for PLM vs ERP.

It is in your highest interest to use technology just to get benefit and at the same time, your effort should be important to understand the ins & outs of both systems.

For all of people, it is mandatory to bring the product to the market efficiently creating the chance to bring the customer. The best technology brings you a competitive edge among manufacturers and automatically, you will gain a good profit margin. . The right technology will also boost your efforts of you, complete your business goals and even help you come closer to your end customers.

What is ERP (Enterprise Resource Planning)?

When you come to know the difference between PLM and ERP, you should come to know first the definition of PLM and ERP separately. ERP carries the full form of Enterprise Resource Planning and it works through the proper System of software. The ERP software brings the biggest advantage in resolving finance and accounting system. It is very important because the system makes sure about your quality product is manufactured in a timely. According to the studies, about 97 percent of mid-sized businesses come for using ERP software.

It works for the betterment of financial activities such as sales, accounting, forecasting, execution, support, customers care, and shipping logistics. A company under this system carries the information company’s finance, sales, and manufacturing department. It brings profit with a real-time picture of the financial status. With the ERP system, a company can track the order by production and delivery.

How does ERP work?

This software works for quality products in a cost-controlled manner once they have been approved. According to a survey, almost 97 percent of mid-sized companies come to use ERP applications. It is important to know that this software is considered essential software as it also works for Oracle ERP, SAP, Epicor ERP, and Microsoft Dynamics AX. ERP System is used for human resources, purchasing, accounting, order management, and inventory management. It also provides a good amount of transactional data for future business decisions.

How does the ERP system work?

In ERP vs PLM, what’s the difference between both until and unless you come to know the details of ERP and PLM? ERP is an essential business tool that provides you the services of Oracle ERP, SAP, Epicor ERP including Microsoft Dynamics AX & others. It is used for manufacturing, human resources, accounting, inventory management, distribution, customer service, purchasing, and many more. This one also provides lots of transactional data in need of financial position and future business decisions. But ERP gives you better results when ERP and PLM systems work together.

What is PLM (Product Lifecycle Management)?

The full form of PLM comes with the name of Product Lifecycle Management software, solutions, and systems. PLM solutions allow anyone involved in design, development, and manufacturing to work collaboratively with one set of comprehensive, accurate, up-to-date information.

How does PLM work?

In four ways, the PLM software comes to work and ways Product concept, Product Design, Production, and Product Distribution & Management.

- Product Concept – The product concept begins with a concept or idea for new products. A good PLM will allow designers to track the evolution of a new product easily even in the product lifecycle.

- Product Design – For the design phase, the designers will have the power to design the product into reality. The work includes prototypes and mock-ups. This ensures the teams work with the file in need of product development. This particular software provides all the information for product design and it ensures the team the file for mind-blowing presentation. The result is a design system it is completely connected.

- Production – Using data, the product enters the manufacturing phase. A business runs with the sourcing of materials, origin, costs, and productivity. PLM system comes as variables during production and without them, they will come with unexpected costs and delays.

- Product distribution and Maintenance – The last stage of the product cycle comes with proper distribution & maintenance. It includes warehousing, distribution, and sales. It tries to keep a record whenever the product enters the market.

How does PLM work?

It works under the supporting processes which define the brand, engage your customers and even differentiate the product in the market is known as PLM vs ERP. This software delivers the truth about your product in need of product development. It works in four ways like product concept, product design, production, and product distribution and maintenance.

The difference between ERP and PLM systems?

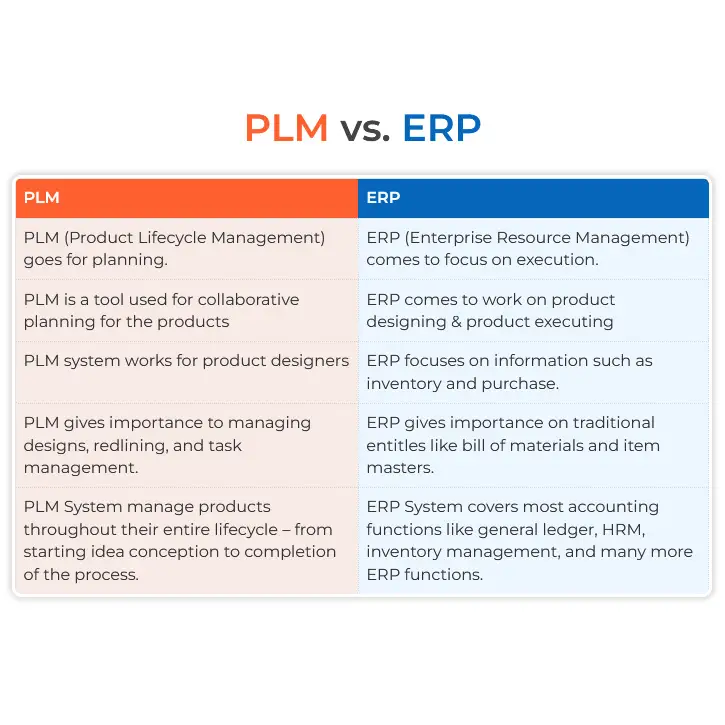

| ERP | PLM |

| ERP (Enterprise Resource Management) comes to focus on execution. | PLM (Product Lifecycle Management) goes for planning. |

| ERP comes to work on product designing & product executing | PLM is a tool used for the collaborative planning of the products |

| ERP focuses on information such as inventory and purchases. | PLM system works for product designers |

| ERP gives importance to traditional entities like bills of materials and item masters. | PLM gives importance to managing designs, redlining, and task management. |

| ERP System covers most accounting functions like general ledger, HRM, inventory management, and many more ERP functions. | PLM System manages products throughout their entire lifecycle – from starting idea conception to completion of the process. |

How do ERP and PLM work together?

Though PLM and ERP are different from one other regarding work procedures, they can work together systematically sometimes. These enterprise systems with their working effort can help you with the Return on Investment.

Under ERP and PLM systems, PLM software manages the single point of product using ERP just to manage product finances and resources. For example, with the help of BOMs, ERP can come to generate accurate purchasing and record of inventory management using unified management. It is good to know that ERP systems come to pick up from PLM solutions and finalize the products.

The design, development, fitting, sampling, and assortment with all other activities create great products that have already been signed by the product-based ERP system. As a result, the combined form of two software comes to improve extraordinary business performance with the actual necessities. Many ERP providers already have started to develop accurately the platforms of their PLM.

Under the combined form of ERP & PLM, your organization creates a powerful source of information, data, and workflows. It can come to create easily and deliver products from idea creation through design for manufacturing and distribution.

Now you have got a better understanding of how PLM and ERP run both with positive efforts on the profit of the entire company and you can understand ERP vs PLM and what’s the difference. Even you can better understand investment in both.

PLM & ERP integration Benefit

Though there must be a difference between PLM and ERP, the integration of both carries benefits. Often, PLM gets associated with engineering. Most people don’t realize the actual management system with ERP. If the PLM system can bring implementation of ERP, then undoubtedly, you need to focus on the benefits in your organization. Even your organization will have unified control in the manufacturing process. As there must a competition in the market in need of delivering the right product at the right time, the price should be budget-oriented.

With the help of PLM and ERP systems, you can increase collaboration for your organization. Without anyone like ERP or PLM, you have to consume and manage inaccurate data in the designing and engineering sector and the activity brings your organization at risk of management.

But the two solutions come to create one single version of the product and it helps to reduce errors in the product, documents, and even product versions. The integration of ERP and PLM systems will enable your organization more agile and active in the activities like traceability, delivery, innovation, and cost. It helps your manufacturing process easily.

The risk of ERP implementation without PLM

Running a business with an ERP system will bring a gap in the process of manufacturing but business comes complete with ERP and PLM systems. The company with the ERP system often comes to struggle with organizing, the most important part of the business. The production in the office and shop comes costly often.

By implementing a PLM system beforehand, a company comes to be confident about the product information is accurately managed by ERP. The ERP system comes to be designed by BOM for transactional needs only. The engineering department requires accurate information to track design changes and collaborate product data.

It is good to know that an organization needs implementation of an ERP system but without PLM, risk managing product changes come. That means PLM comes essential when you need to know completely ERP and PLM systems.

Conclusion

Technology is the right weapon to make the business profitable through customer integration, more productivity, and a high margin of profit. Go through the details of PLM vs ERP and use them for the business better.

PLM vs ERP FAQs

What are the stages of PLM in ERP?

Stages of the PLM include the start to the end of the product. It covers ideation, design, prototyping, manufacturing, service, and end-of-life management.

What is the capability of PLM?

PLM capability includes product design, demand management, supply chain planning, sourcing, inventory management, and multi-channel distribution.

What is the capability of ERP?

ERP capability includes order processing, financial accounting, inventory management, purchasing, and manufacturing management.